TR EN

Industrial

- Stainless Steel Pipes

- Stainless Steel Rectangular Tubes

- Stainless Welding Connection (BW) Fittings

- ISO (1127) Clamp Parts

- Threaded Stainless Steel Fittings

- Stainless Steel High Pressure

Socket Welded and Threaded Fittings

2000 LBs / 3000 LBs / 6000 LBs / 90000 LBs - Socket Welded High Pressure Fittings

- Stainless Steel Flanges

- EN 1092-1 Standards

Stainless Steel Flanges - PN6 Flanges

- PN10 Flanges

- PN16 Flanges

- PN25 Flanges

- ANSI & EN 1759-1 Standards Stainless Steel Flanges

- Class 150 Flanges

- Class 300 Flanges

- Aluminium Flanges

- Stainless Steel Valves

- Threaded Ball Valves

- Socket Welded Ball Valves

- Flanged Ball Valves

Hygienic

- Alfa Laval

- Hygienic Fittings According To DIN Standard

- Hygienic Reducers (DIN 11852)

- Hygienic Bends (DIN 11852)

- Hygienic Tees (DIN 11852)

- Hygienic Union Parts (DIN 11851)

- Hygienic Fittings According To

ISO 2037 and SMS Standard - Hygienic Reducers (ISO 2037)

- Hygienic Bends (ISO 2037)

- Hygienic Tees (ISO 2037)

- Hygienic SMS Union Parts (ISO 2037)

- Hygienic Clamp Parts (ISO 2037)

- Sight Glass & Spanners for Unions

- Sanitary Valves and Automation Items

- Features of Hygienic Butterfly,

Sampling and Check Valves - Hygienic Butterfly Valves

- Butterfly Valve Bodies

- Hygienic I Type Butterfly Valves

- I Type Butterfly Valve Bodies

- I Type Butterfly Valve Handles

- Hygienic Sampling Valves

- Hygienic Check Valves

- Single Seat Actuated And Manuel Valves

- Regulated Valves

- Control Heads and Otomation Switches

- Valve Control Heads

- Automation Indication Units

- Sanitary Tank Equipment

- Tank Cleaning Heads

- Tank Covers

- C Type Circular Tank Covers

- O Type Oval Menhole Tank Covers

- R Type Rectangular Tank Covers

- Tank Agitators

- Sanitary Pumps

- Enox

- Hygienic Fittings According To DIN Standard

- Hygienic Reducers (DIN 11852)

- Hygienic Bends (DIN 11852)

- Hygienic Tees (DIN 11852)

- Hygienic Union Parts (DIN 11851)

- Hygienic Clamp Parts (DIN 32676)

- Hygienic Fittings According To

ISO 2037 and SMS Standard - Hygienic Reducers (ISO 2037)

- Hygienic Bends (ISO 2037)

- Hygienic Tees (ISO 2037)

- Hygienic SMS Union Parts (ISO 2037)

- Hygienic Clamp Parts (ISO 2037)

- Hygienic Sight Glasses, Filters

and Stalked Pipe Hangers - Hygienic Inline Sight Glasses

- Inline Sight Glasses

According To DIN Standard - Inline Sight Glasses

According To SMS Standard - Hygienic Union-Type Sight Glass

- Union Male Angle-Type Strainers

- Stalked Pipe Hangers

- Hygienic Valves

- Hygienic Butterfly Valves

- Hygienic Butterfly Valves

According To DIN Norm - Hygienic Butterfly Valves

According To SMS (ISO 2037) Norm - Hygienic Check Valves

Instrumentation

- LET-LOK Tube Fittings

- Pipeline Precision Instrument Pipe Fittings

- Valves

- Other Fittings

Hygienic / Alfa Laval  / Sanitary Valves and Automation Items / Hygienic Check Valves / LKC-2 Check Valve Features

/ Sanitary Valves and Automation Items / Hygienic Check Valves / LKC-2 Check Valve Features

/ Sanitary Valves and Automation Items / Hygienic Check Valves / LKC-2 Check Valve Features

/ Sanitary Valves and Automation Items / Hygienic Check Valves / LKC-2 Check Valve FeaturesLKC-2 CHECK VALVE FEATURES

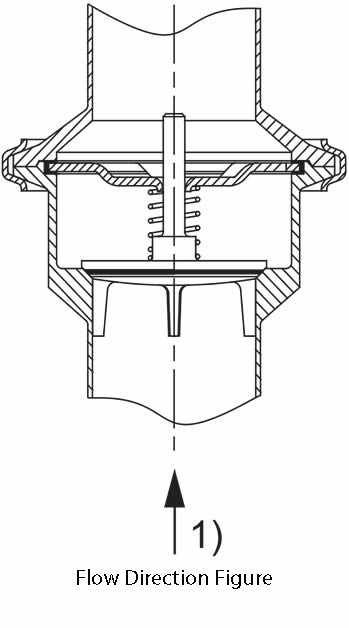

Welded Connection | IMPLEMENTATION LKC-2 check valve has been designed to prevent reverse flow in stainless steel pipelines. Operation Principle LKC-2 valve is opened when the pressure under the plug is more than the pressure over the plug and string strength. Valve is shut off when the pressure is balanced. It is also shut off when there is a balance of a higher counter-pressure. A higher counter-pressure value pushes the valve sealing plug against the valve seat. Standard Design The valve body consists of two parts, which are a combined with a clamp ring and a special sealing component that ensures hygienic sealing. Four-pillar, spring loaded valve bears the sealing plug with an O-ring gasket. LKC-2 valve is a welded connect6ion for ISO or DIN norms. | |

Standard Welding | Material.................................................: AISI 304 stainless steel or AISI 316L Sealing Components.............................: EPDM Surface Quality .....................................: Semi-lustrous Valve can be suppled as welded connection in compliance with ISO2037 or DIN 11850 norms. The pressure difference required to open the valve when it is vertically installed on the pipeline is approximately 6 kPa (0,06 bar). (see Figure) Maximum product pressure ........................ : 1000 kPa (10 bar) Maximum temperature ................................ : 140 °C (EPDM) Minimum temperature ................................. : -10 °C | |

| OPTIONAL MATERIAL QUALITIES A) Sealing component coming into contact with fluid Nitrile (NBR) or viton (FPM). Please indicate the following specifications when ordering. • Gauge • Material Quality, AISI 304 or AISI 316L • Please indicate if the gasket is not standard EPDM. | |