TR EN

Industrial

Hygienic

Instrumentation

Hygienic / Alfa Laval  / Sanitary Valves and Automation Items / Hygienic Sampling Valves / Hygienic Single Seat Sampling Valve

/ Sanitary Valves and Automation Items / Hygienic Sampling Valves / Hygienic Single Seat Sampling Valve

/ Sanitary Valves and Automation Items / Hygienic Sampling Valves / Hygienic Single Seat Sampling Valve

/ Sanitary Valves and Automation Items / Hygienic Sampling Valves / Hygienic Single Seat Sampling ValveHYGIENIC SINGLE SEAT SAMPLING VALVE

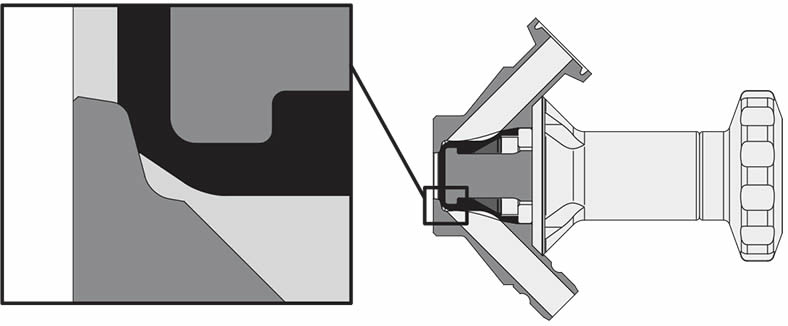

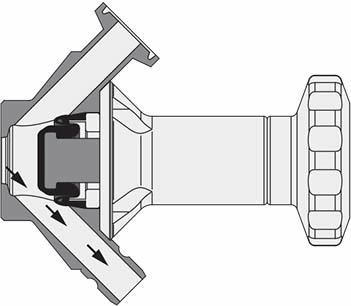

| IMPLEMENTATION Unique Sampling valve is a single seat valve that is designed to conduct sterilization process before and after each sample. Valve body and fittings are manufactured from monoblock material to avoid cracks and problems related to welding. OPERATION PRINCIPLES Sterilization: When the valve is closed, the channel between the valve paths is opened for sterilization. If steam is used, placing a small safety valve (optional) on the outlet is recommended. Sampling: When the valve is opened, the body and membrane gasket is withdrawn and allows the passage of sample. STANDARD DESIGN The valve consists of three parts: valve body, one actuator and membrane gasket. Rubber membrane gasket is located on the body of the actuator and acts as a stretchable plug. The valve bodies and actuators may be relocated. In the event that single seat valve, valve or actuator is changed using a renewal package, it can be converted to a dual-seat valve. |

| TECHNICAL DATA Temperature Temperature Range ........................................ 1 °C - 130 °C Maximum Sterilization Temperature Dry steam (2 bar) ............................................ 121 °C The steam should be dry because condensed water damages the membrane gasket. It is recommended to replace the membrane gasket after each 500 processes of sampling/sterilization, depending on the operating conditions or experience. Pressure Max. Operating pressure ................................ 600 kPa (6 Bar) Min. Operating pressure ................................. 0 kPA (0 Bar) | PHYSICAL DATA Materials Valve Body............................ 1.4404 (316 L) Actuator................................ 1.4301 (304), 1.4404 (316 L) Membrane gasket ............... EPDM, silicone |

Valve Consists of Three Different Sizes: SIZE 4: For low-viscosity products such as water, wine and milk Up to 100 cp viscosity, maximum particle size: 2.5 mm SIZE 10: For high-viscosity products such as fruit yogurt, syrup and ice cream. Up to 1000 cp viscosity, maximum particle size: 7mm SIZE 25: For high-viscosity products such as jam. | Valve Bodies • Tank (Welded Connection) • Pipe Liner (Welded Connection) • Clamped Valve heads • Handle • Pneumatic Actuator (5-8 bar air supply) |

| VALVE CLOSED Closed Valve: When the valve is closed in the “sterilization position”, the channel between the valve paths is opened for sterilization. | |

| VALVE OPEN Open Valve: When the valve is opened in the “Sampling position”, the body and membrane gasket is withdrawn and allows the passage of sample. |

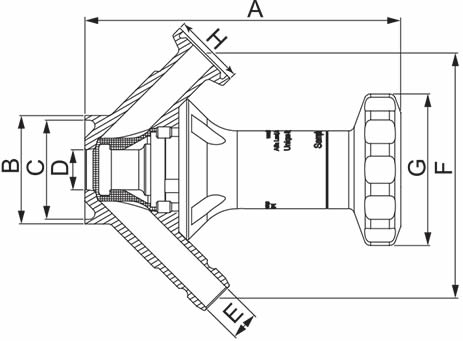

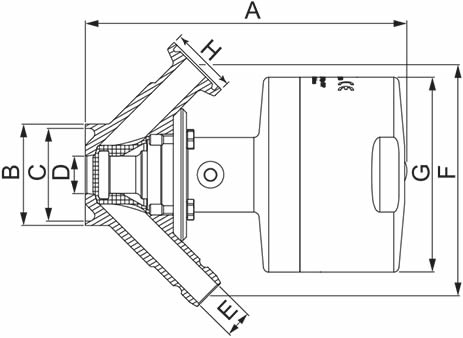

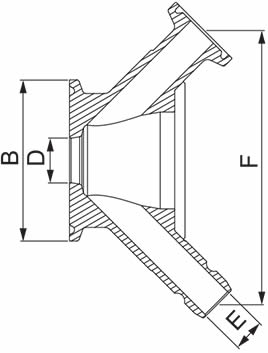

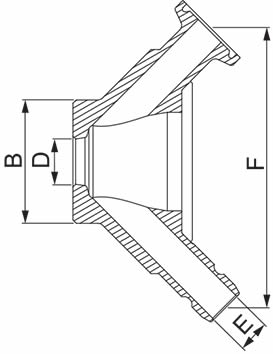

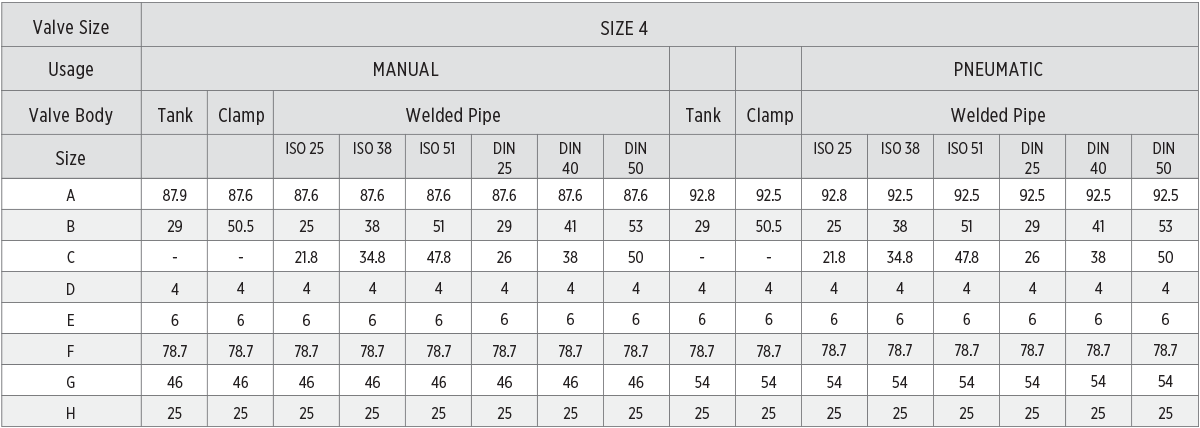

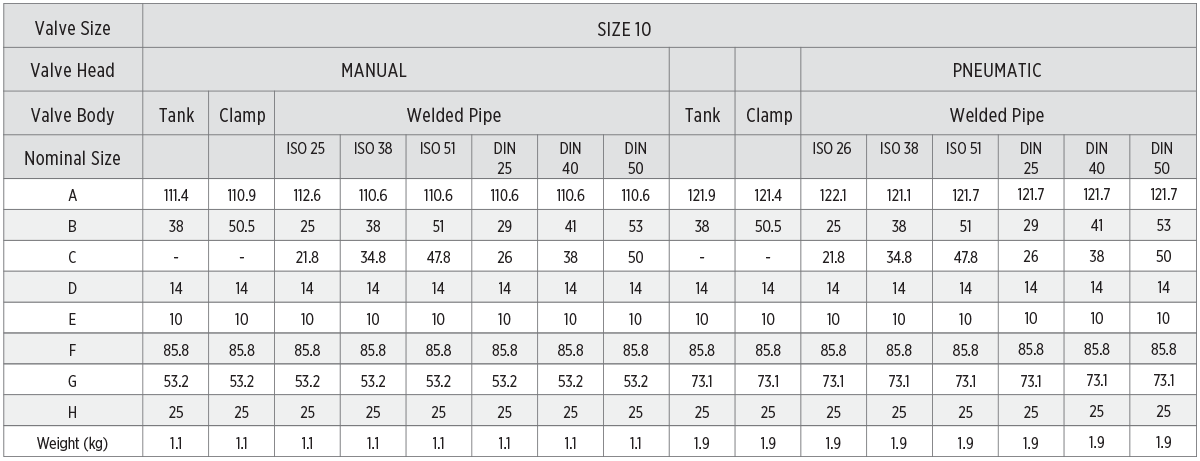

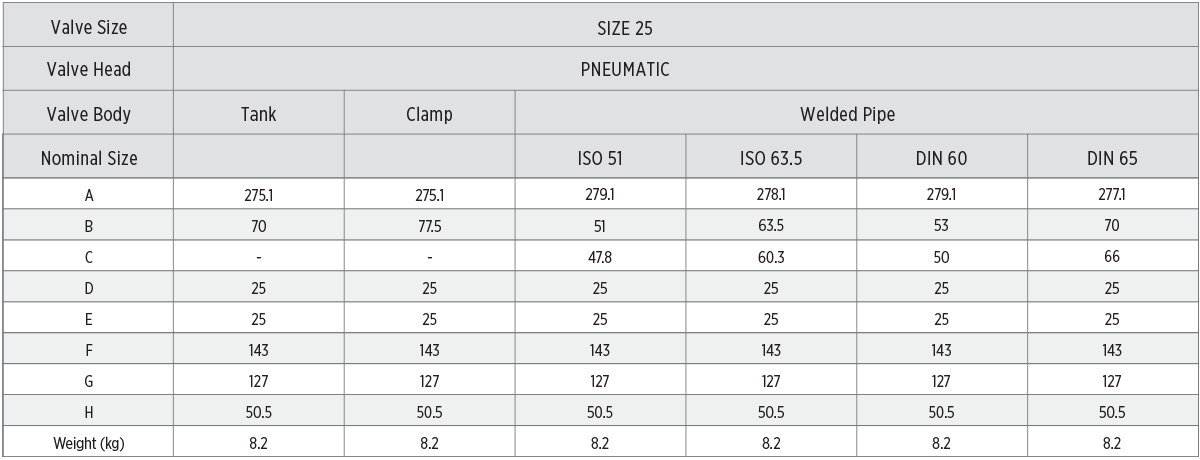

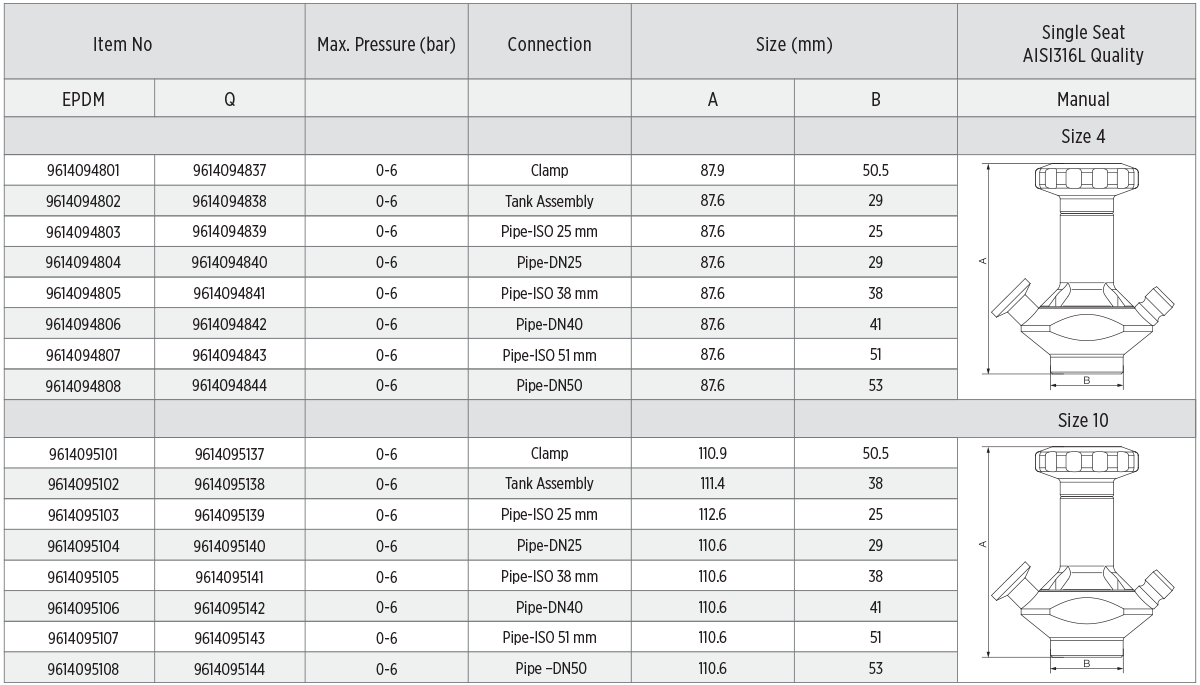

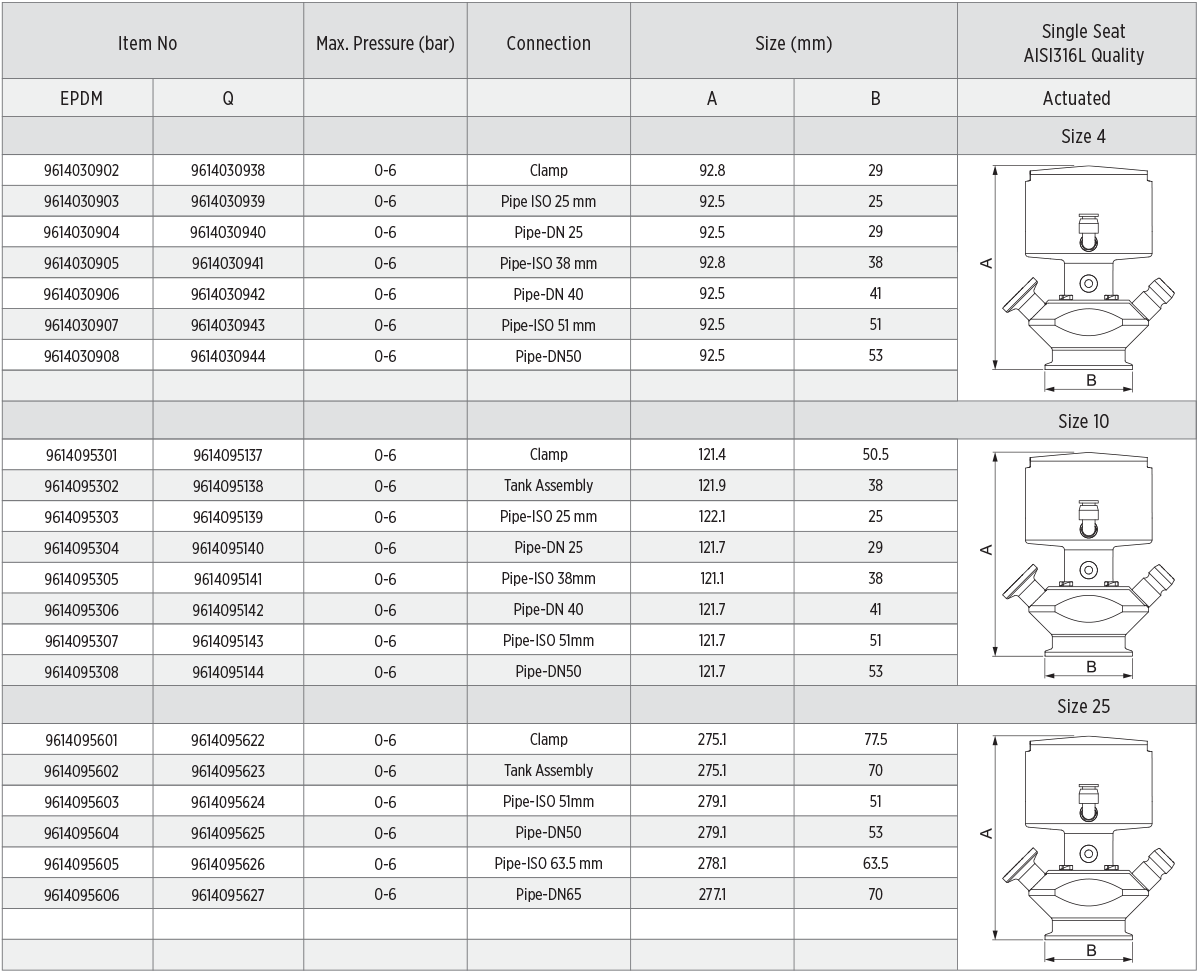

DIMENSIONS

| Manual Valve: Pipe Welded (Liner) Connection | Pneumatic Valve: Pipe Welded (Liner) Connection | |

|  | |

Valve Body: Clamp Connection | Valve Body: Welded tank | |

|  |

|

|

|

MANUAL DIMENSIONS and PRODUCT NUMBERS

Product Code: 5349

|

ACTUATED DIMENSIONS and PRODUCT NUMBERS Product Code: 5349  |